Lumber Products

Lewis Lumber Products, along with Dwight Lewis Lumber Company, manages, produces and distributes hardwood lumber products. Here are a few facts about our products:

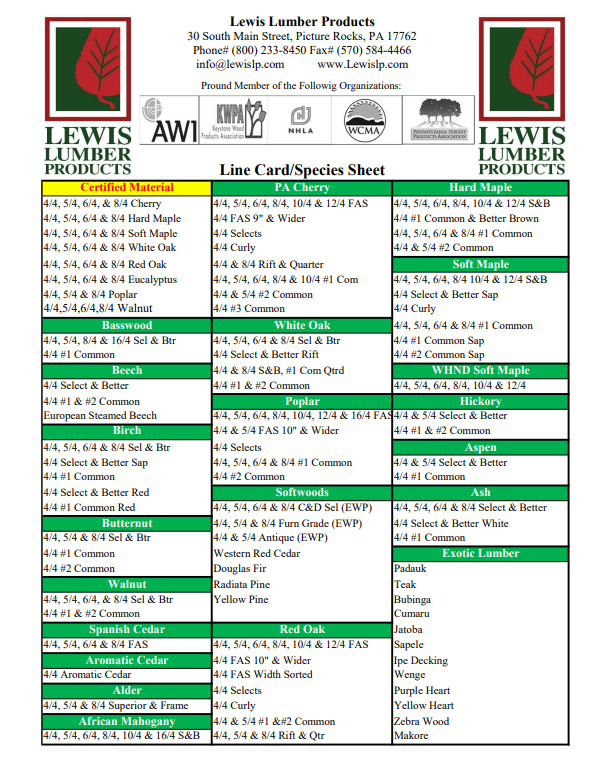

- 53 different species of wood

- 28 domestics and 25 exotic species

- 18 domestics native to PA

- 45 hardwood species and 8 softwood species

- 96% of our footage volume is made up of domestic species

- 87% of our sales revenue is made up of domestic species

- 80% of our footage volume is made up of domestic species (procured in PA and NY)

Located in Northcentral Pennsylvania, renowned for the highest quality temperate hardwood forests in the world, Lewis Lumber Products uses timber carefully harvested by our sister company, Dwight Lewis Lumber. We strive to use only sustainable forest resources that cause negligible disturbance to the environment.

As logs are sawn into lumber, dried and graded, experienced and skilled people at Dwight Lewis Lumber are in place to ensure that waste is minimized while resources are maximized. Lewis Lumber Products then sorts and mills the fine wood guaranteeing only quality products reach your door. From the experienced and helpful sales staff to the knowledgeable and quality conscious production crew we strive for the highest standard of excellence.

A South American hardwood, IPE (Tabebuia serratifolia) is one of hardest woods on Earth. Because of its hardness and ability to resist decay, IPE is superior for decks, patios, piers, boat docks, outdoor furniture, walkways and poolside benches. IPE requires no chemical preservatives to keep it smooth and splinter free and it is naturally safe.

With a durability rating of 25-plus years by the U.S. Forest Products Lab, IPE is competitively priced and comparable to cedar, redwood or composite decking.

Wood Selection Tips

Not sure which grade to select when shopping for wood?

- Grade A: FAS / F1F, Select and Better: This is the highest quality of hardwood lumber and will yield long, clear pieces with very little waste.

- Grade B, #1, Common: A great value for the woodworker looking to get several long, wide cuts, or longer narrow cuts in a board.

- Grade C, #2, Common: This grade of lumber is good for the woodworker looking to use the natural characteristics (knots, worm holes, discoloration) or looking for 1-foot or 2-foot cuts. Also good for small crafts and interior furniture parts.

Wood Characteristics

Lewis Lumber Products offers 19 varieties of hardwoods and softwoods including aromatic cedar, ash, basswood, beech, birch, black walnut, butternut, cherry, curly cherry, curly maple, elm, Eastern White Pine, hard maple, hickory, mahogany, red oak, soft maple, white oak and yellow poplar. Browse this site for photographs, common characteristics and common uses of each lumber variety that we stock.

More than just a lumber company, Lewis Lumber Products is dedicated to providing the highest quality lumber products.

Lewis Lumber Products

P.O. Box 356

30 S. Main St.

Picture Rocks, PA 17762-0356

USA Phone: (800) 233-8450 / Fax: (570) 584-4466

E-mail: [email protected]